INDUSTRIAL AREAS

FACILITIES

The covered industrial premises located in Larissa cover an area of 12,500 sq.m.

With easy access from the old and the new Thessaloniki-Athens highway, it has the ability to supply Greece and the Balkans with its products.

Production

The production process of both the tiles and the rest of the company's products (paving, curbs, paving, cement blocks, tiles) is fully automated with the most modern mechanical means. Indicatively, the production capacity in roof tiles 60,000 pcs / 8 hours and in paving 2,000 m2 / 8 hours

PRODUCTION PROCESS

Production Stages

The tile production process is fully automated and consists of 6 stages.

1

Storage & supply of raw materials

4 different types of sand are aggregatesd and automatically received and stored in co-located silos with a total capacity of 600t. As a uniting material of the mixture, two already cements are used which are supplied and stored by air carrier in a 200t silo.

2

Stage: Mixing of raw materials and production of mixture.

Sand, cement, pigments - oxides, fluidizers - plasticizers and water are used for the production of the tile mixture. Weighing and mixing of all materials is done automatically.

3

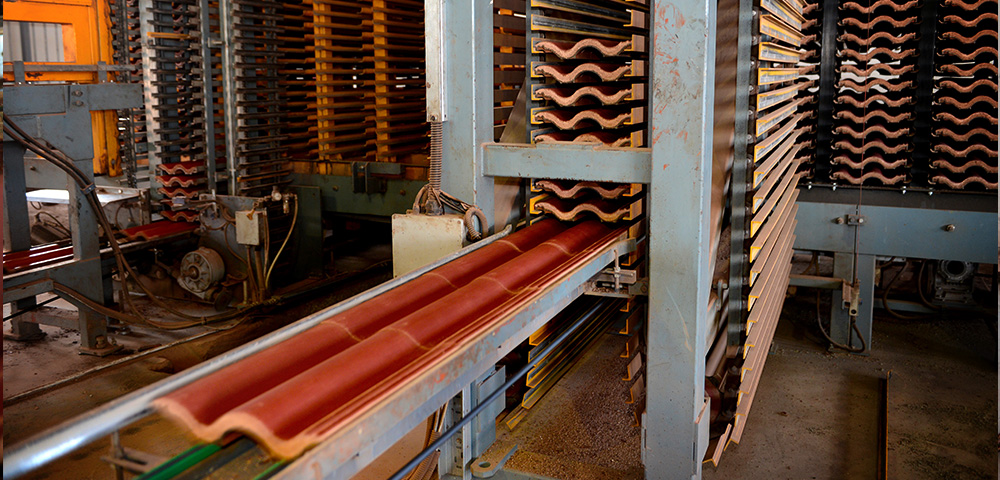

Stage: Shaping the tile and 1st paint

The ready mixture is guided by a conveyor belt to the tile press. This is the time when it is pressed and cut at a speed of 130 roof tiles per minute. Immediately after that, the first paint with colored acrylic waterproofing agent is carried out.

4

Stage: Drying - Baking of roof tiles.

The roof tiles are then automatically placed on shelves. The full shelves are now guided by robots into the ovens. They remain there for 8 hours at a temperature of 70οc.

5

Stage: Quality control cleaning and final painting.

Before the final painting, a quality control is carried out through a scanner that checks the weight and the geometry.